-

1

Rigorous Raw Material Selection

We only use raw materials from large enterprises

-

2

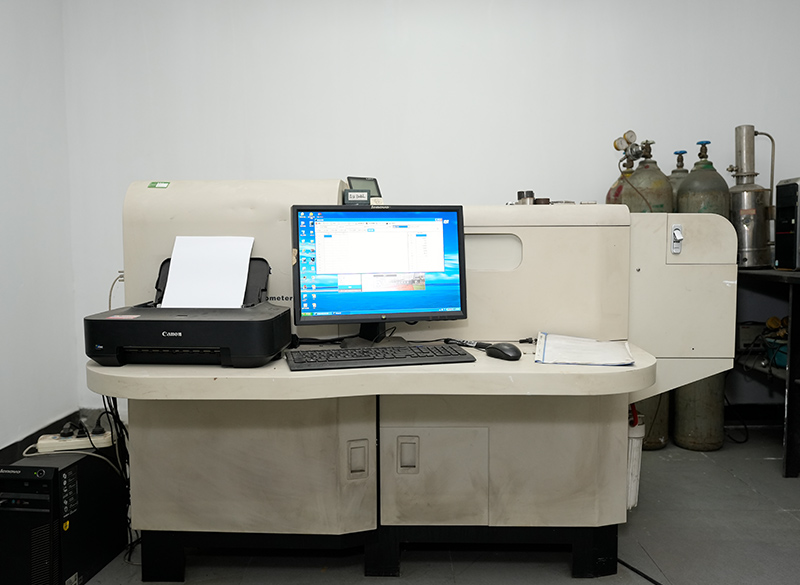

Rigorous Raw Material Selection

We use direct reading spectrometer to test the chemical composition

-

3

Precision Manufacturing

Our company has 28 cold rolling mills and 6 cold drawing mills for precision machining of steel pipes.

-

4

Precision Manufacturing

Our company has a natural gas solution furnace and 2 BA pipe solution furnaces for bright annealing of steel pipes.

-

5

Precision Manufacturing

Perform endoscope inspection and handheld spectrometer sampling inspection

-

6

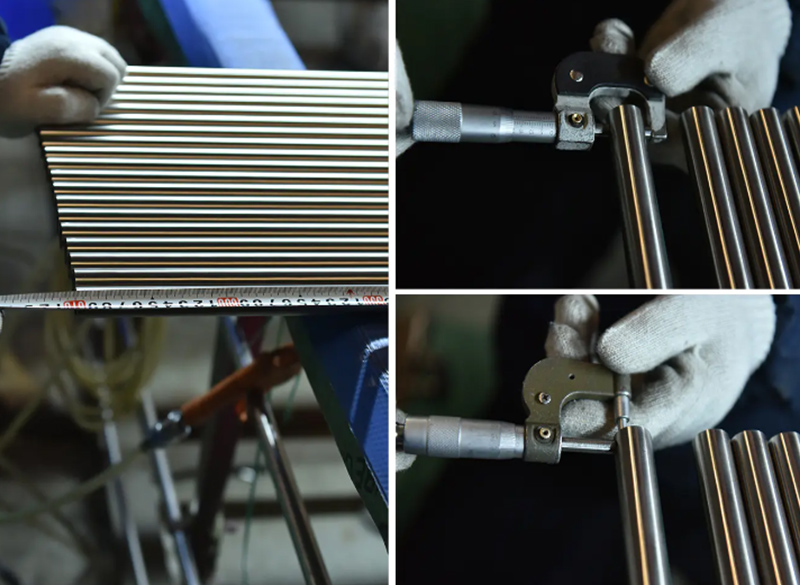

Finished product size inspection

Size inspection & Ring gauge inspection

-

7

Stringent Surface quality inspection

25-meter endoscope inspection& Handheld spectrometer inspection

-

8

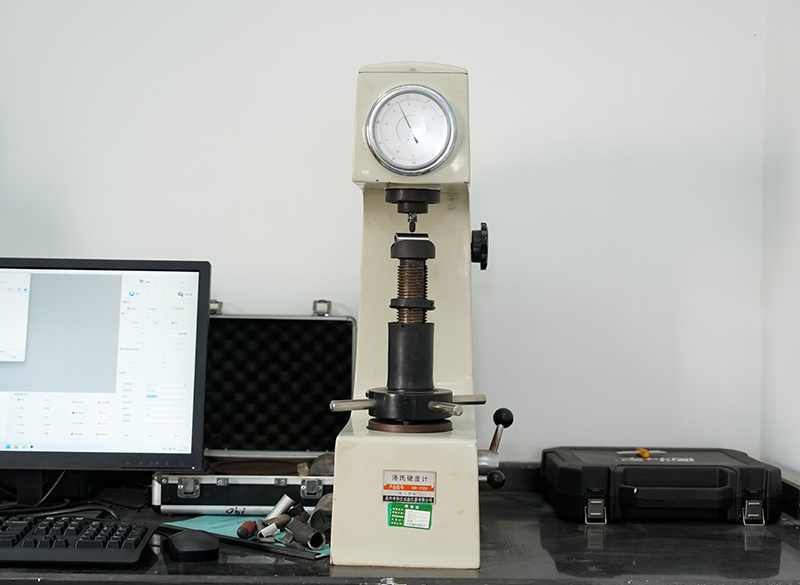

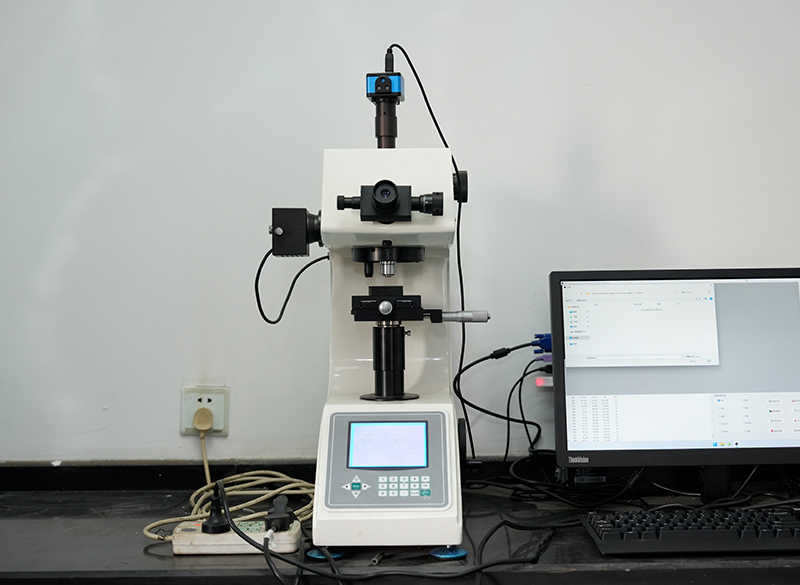

Stringent Surface quality inspection

Vickers hardness tester inspection and Rockwell hardness test

-

9

Mechanical Property Testing

Physical performance tester

-

10

Non-destructive Testing (NDT)

Eddy Current Testing (ECT) & Ultrasonic Testing (UT)

-

11

Non-destructive Testing (NDT)

5-station steel pipe hydrostatic test & Metallographic analysis and detection

-

Mature overall production equipment,

Complete testing equipment,

A complete stainless steel pipeline quality management system

Bring the best quality to your customers.